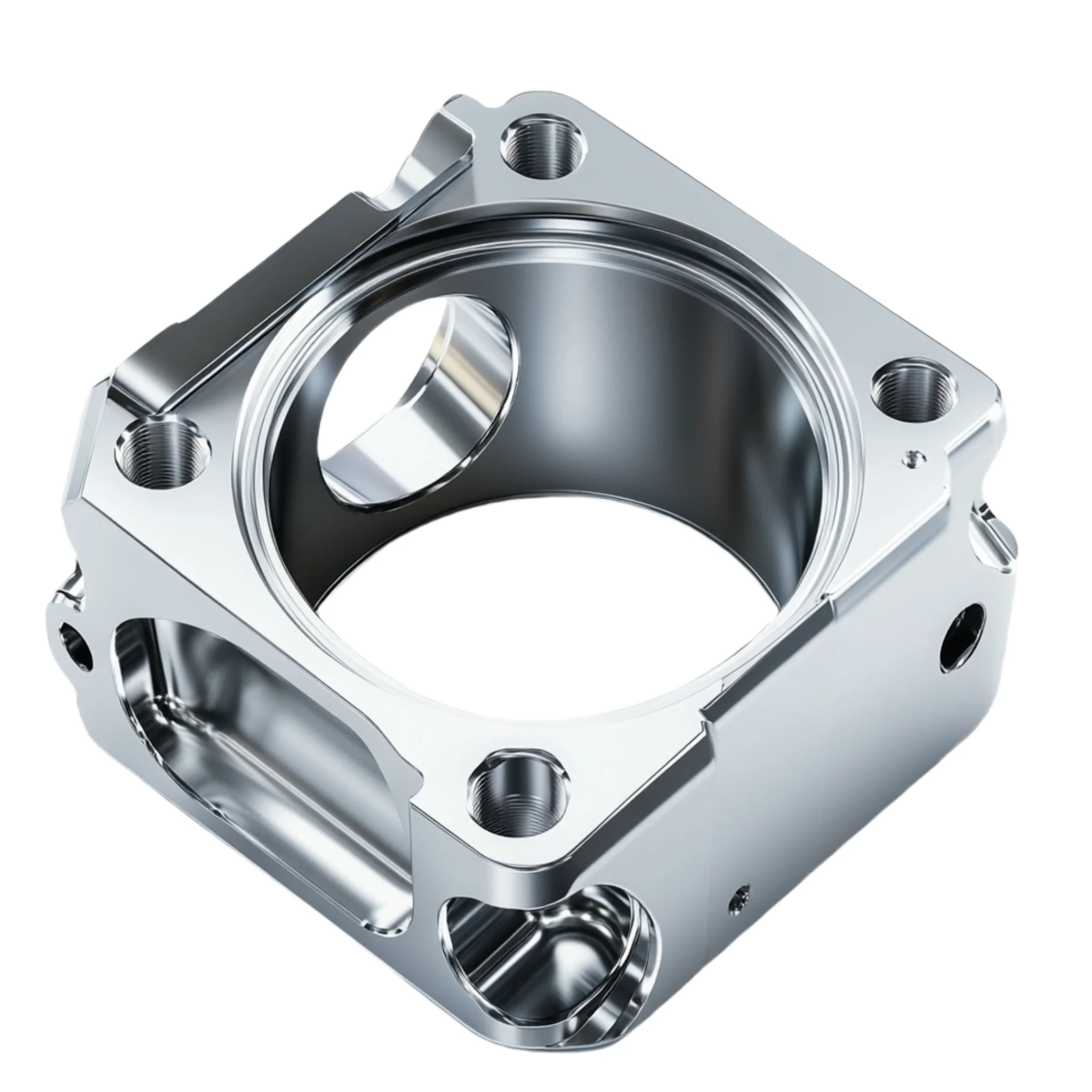

Customized Precision Parts

3-Hour quotation Samples: 1-3 Days

Lead time: 7-14 Days

report Guarantee:

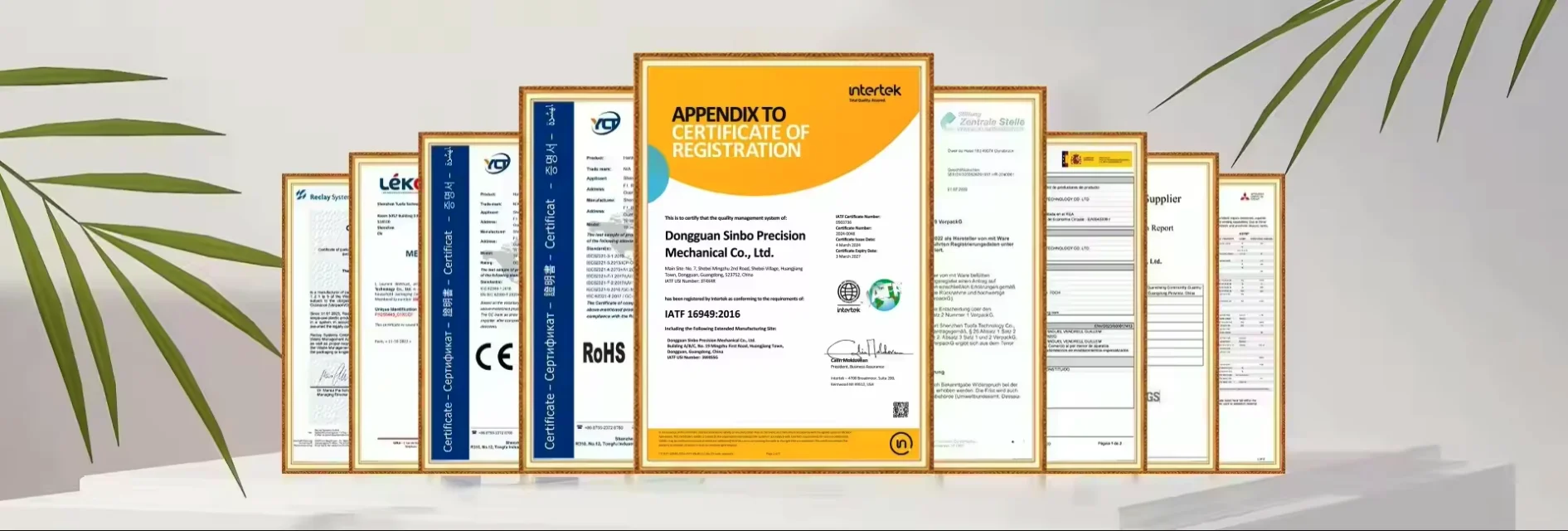

Lifetime After-Sales Service Certificate:Medical,Aviation,Automobile,

ISO13485, IS09001, AS9100, IATF16949

| Sign In | Join Free | My bjjsgy.com |

|

Place of Origin : Guangdong, China

Model Number : Non-standard

Brand Name : Sinbo

Certification : ISO9001:2015

MOQ : 1

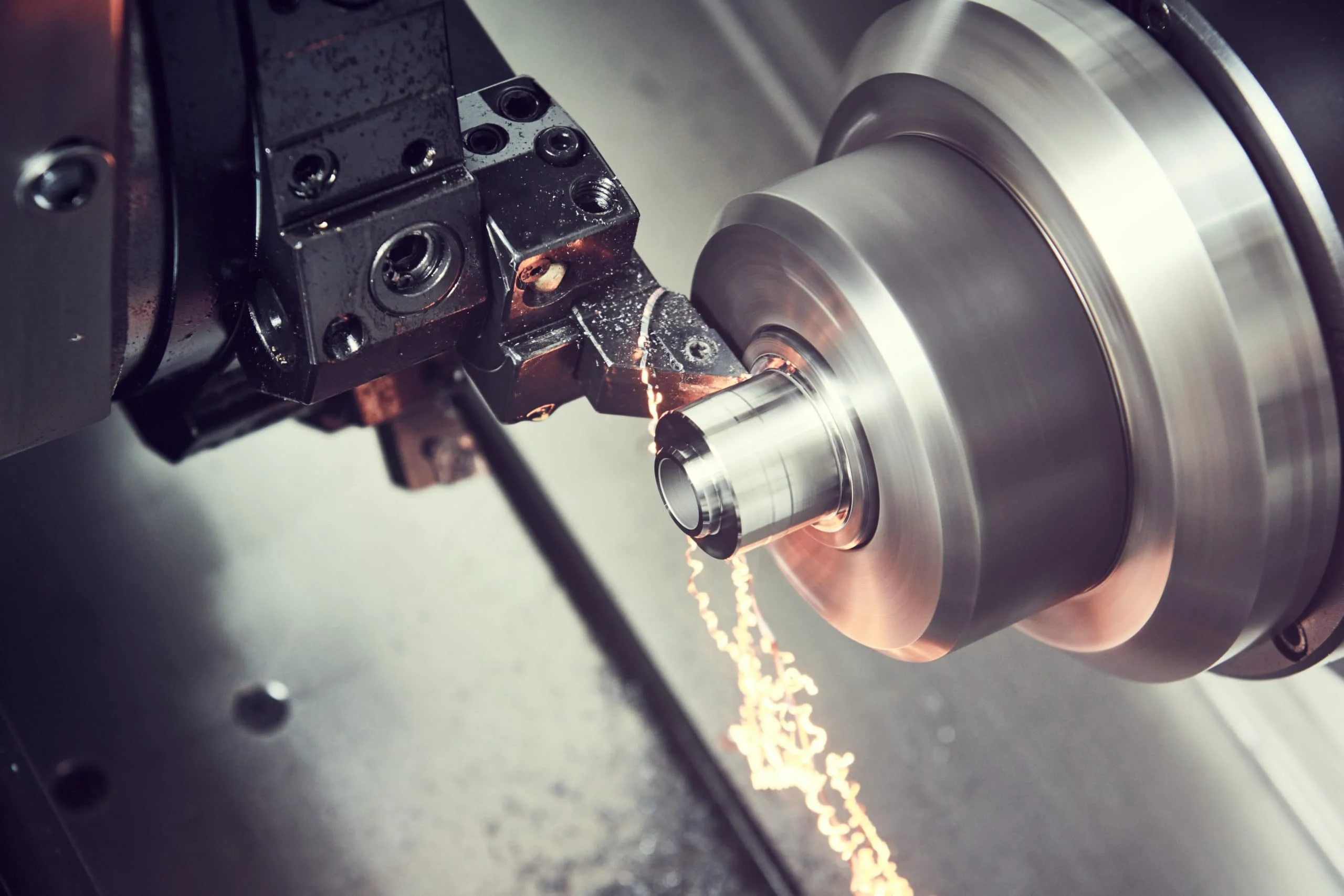

CNC Machining : Yes

Material Capabilities : Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Micro Machining : Yes

Material : Aluminum, Stainless steel, Brass, Copper, Kovar, PEEK, POM

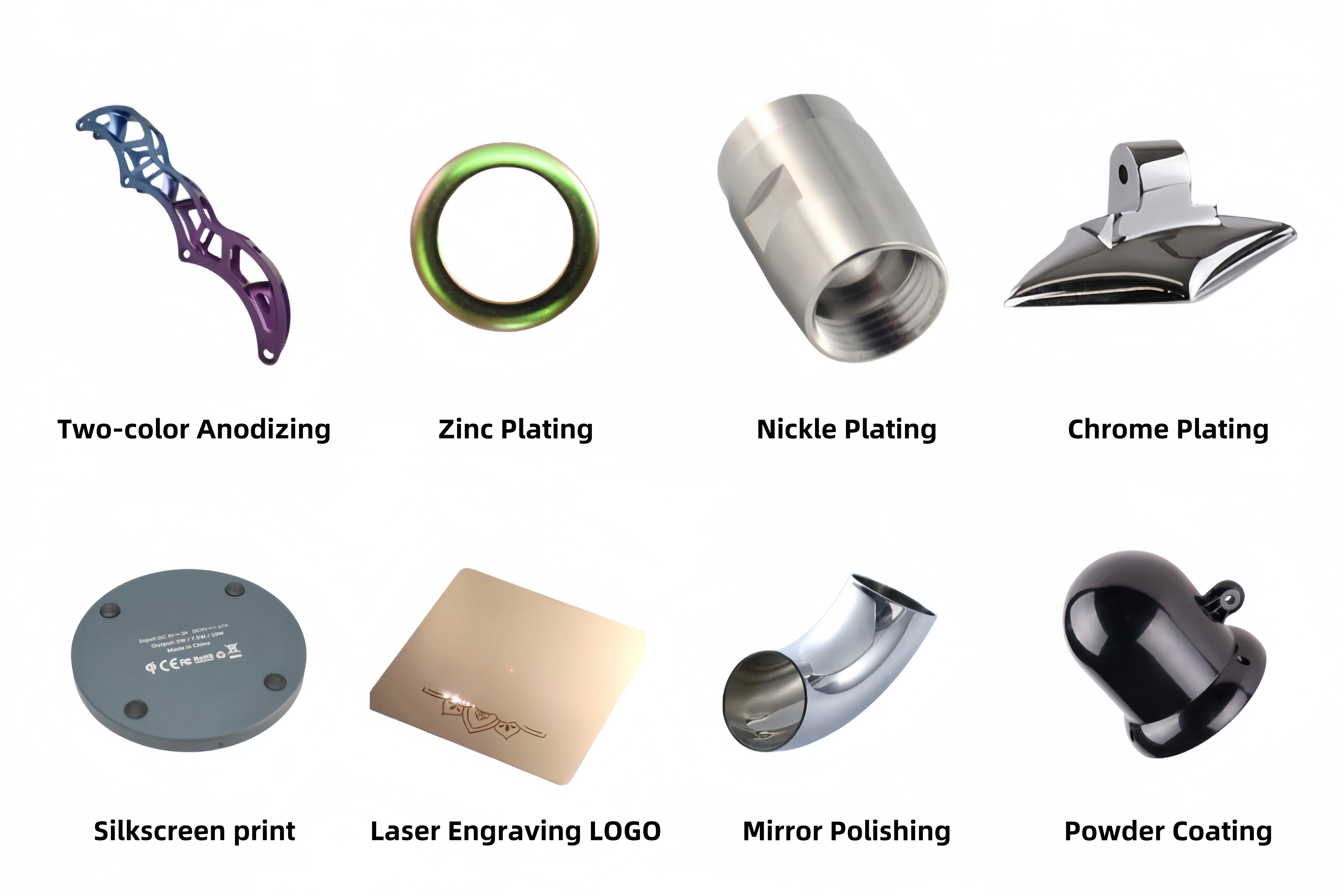

Surface treatment : Painting, plating, sandblasting, passivate, silk screen, coating

Tolerance : +/-0.002-0.01mm

Process : Extrusion enclosure; CNC milling machining

Quality control : 100% Inspection

Machinery Axis : 3,4,5

Surface Roughness : Ra 0.1~3.2

Supply Ability : 300000 Piece/Month

Minimum Order : 1-Piece

Lead Time : 7-14 Days

Sample Time : 1-3 Days

Aluminum Grades : 2024, 5083, 6061, 6063, 7075

Processes | CNC Turning, CNC Milling,Cold Forging,Metal Stamping,Die Casting,Laser Cutting,Bending,Welding,Spinning, Wire Cutting, | ||||||

Material | Aluminum,Stainless steel,Brass, Copper, Carbon Steel, Beryllium Copper,Titanium Alloy,Plastic, etc. | ||||||

Processes | CNC Turning, CNC Milling,Cold Forging,Metal Stamping,Die Casting,Laser Cutting,Bending,Welding,Spinning, Wire Cutting, | ||||||

Surface Treatment | Anodizing,Mirror Polishing,Brush,Sand Blasting,Plating, Powder Coating, Painting,Electroplating,Silk Screen,Engrave,etc. | ||||||

Tolerance | ±0.001mm | ||||||

Surface Roughness | Min Ra 0.1~3.2 | ||||||

|

|

Precision CNC Machining Enclosure with Micro Machining and Anodized Surface for Electronical Applications Images |